Punctured packaging is a nightmare all liquid sauce manufacturers are aware of – not only does it waste the whole packet of sauce, but also it requires employees to do additional cleaning. Many may wonder how they could end this unpleasant experience. Well, we have good news to share – using a vertical form, fill and seal machine (for packaging) along with the Marsh 241D digital hot stamp coder for printing dates, batch numbers, etc., can avoid puncturing packaging! The user can also enjoy benefits like having the coder print automatic updated dates and batch numbers on the packaging (if desired) and excellent print quality! Let’s watch a video of our customer’s Marsh 241D printing on-site:

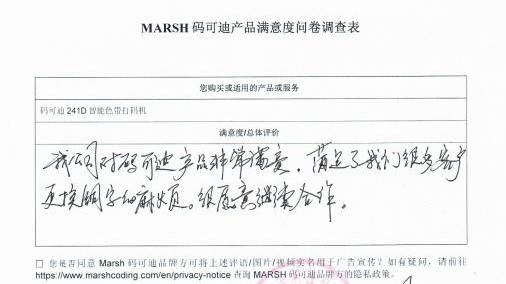

A sauce manufacturing factory had been printing codes with the conventional hot stamp coders – employees had to manually change the brass type characters and wait for the warm-up of print blocks and characters, increasing the lead time in manufacturing and wasting employees’ energies unnecessarily. After replacing their hot stamp coders with Marsh 241D coders, the factory no longer needs to deal with the hassle of using brass type print blocks and characters, significantly increasing the production efficiency. In addition, the reliable Marsh 241D coder eliminates all possible human errors, avoiding unnecessary expenditure due to typographical errors. The sauce manufacturer is beyond impressed by the cutting-edge technology Marsh 241D coder utilises and is more than happy to provide honest, positive reviews.

If your company also produces packets of liquid sauce, Marsh will be your best option in saving cost and time.

To learn more about the Marsh 241D coder, please click on ‘Products’ on the top bar menu -> ‘Marsh 241D Digital Hot Stamp Coder’.